Applied Mechanics Lab - Brown University

Mechanics of Materials

Welcome to the Applied Mechanics Lab at Brown University! We are part of the Solid Mechanics group in the School of Engineering at Brown University.

Our research is focused on applying the tools and techniques of Solid Mechanics to understand the deformation and failure of engineering, biological materials and structures. We study structure-property connections - how small-scale structure in materials gives rise to effective properties at the large-scale. We have investigated structure-property and structure-phenomenon connections in a number of engineering and biological systems. For example, we have used tools from the field of applied and computational mechanics to understand how sub-micrometer scale architecture in structural biological materials affects their deformation and failure behavior.

The stiction failure phenomenon in Microelectromechanical systems (MEMS) devices is a critical impediment to their full commercialization. In order to avoid such failure, the ability to quantify the work of adhesion of adhered microbeam is required. Previous research applies interferometric techniques to measure the beam’s unadhered length and related the work of adhesion for an adhered microbeam to that length. However, this is labor intensive and needs to build a large array of microbeams.

We proposed a new vibration-based technique that can be easily implemented with existing atomic force microscopy tools or similar metrology systems. In this technique, we used a geometrically nonlinear beam theory to model the adhered microbeam and found a new relation between the work of adhesion and the unadhered length. Then, we derived a closed-form approximate relationship between the microbeam’s natural frequency and its unadhered length. We also did three-dimensional nonlinear finite-element analysis to check the accuracy of this analytical formulation. This technique could be useful in designing and building more reliable MEMS devices with microscopic moving parts.

Figure 1

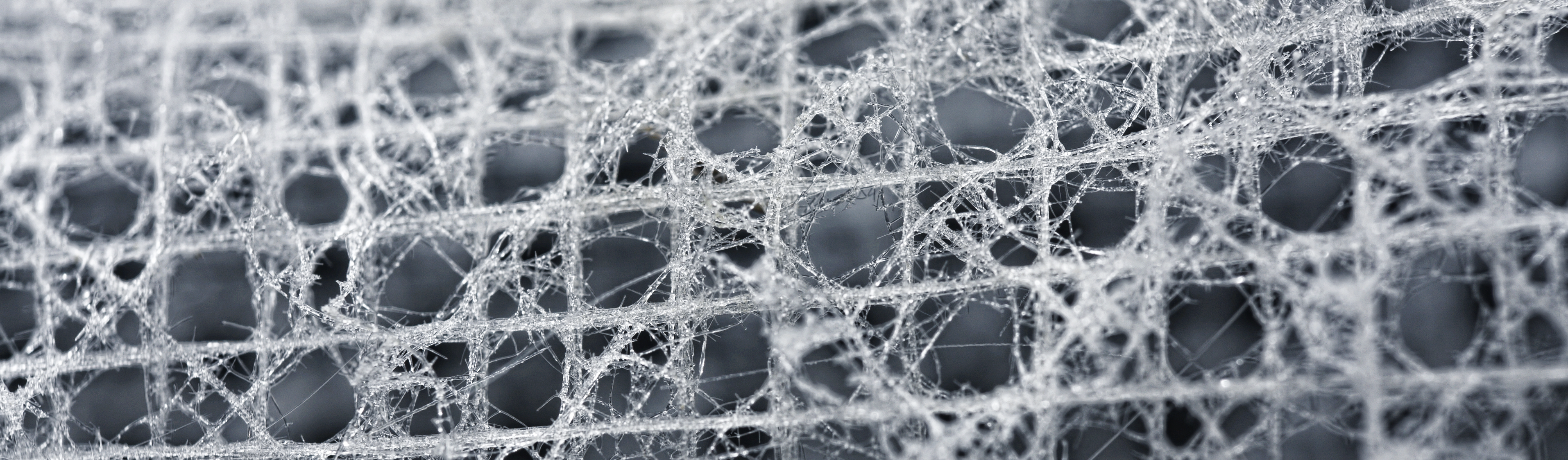

In most engineering materials, from steels to ceramics, strength and toughness are mutually exclusive. This is a critical bottleneck for aerospace, transportation, and energy production technologies. However, some structural biological materials, such as bone and shell, simultaneously have both high strength and high toughness relative to the weak and brittle ceramics (e.g., calcium carbonate and silica) from which they are primarily composed. These structural biological materials are often heterogeneous and consist of ceramic and organic phases combined in intricate patterns at the micrometer scale (Figure 1). The arrangement of these phases, which is known as the material’s architecture, is believed to be the key to their remarkable combination of strength and toughness. We use the anchor spicules of the marine sponge Euplectella aspergillum as a model system for investigating how architecture in structural biological materials affects strength and toughness properties.

Figure 2

The anchor spicules are root-like fibers that fasten the sponge to the seafloor (Figure 2 B). Each spicule is approximately 50 \(\mu\)m in diameter, up to 10 cm in length, and is composed of hydrated silica (Figure 2 C). When viewed in cross-section, an anchor spicule consists of a \(\approx\)10 \(\mu\)m silica core that is surrounded by a coaxial assembly of \(\approx\)25 cylindrical, silica layers (Figure 2 D). Adjacent silica layers are separated by thin proteinaceous interlayers. While the spicules are composed primarily of glass, they are surprisingly flexible and can even be tied in knots before breaking.

Figure 3

One of the primary questions underlying our research is: How much does a spicule’s architecture enhance its toughness and bending strength? We have investigated this question by performing flexural tests on the anchor spicules to measure their bending strain at the point of failure, as well as their crack growth resistance (Figure 3 and Movie 1). We compare these strength and toughness properties to the properties of spicules from a related sponge (Tethya aurantia) that have a similar chemical composition but lack the lamellar architecture.

Through this comparison we have found that:

Movie 1

The following resources from the University of Auckland provide a foundational overview of solid mechanics.